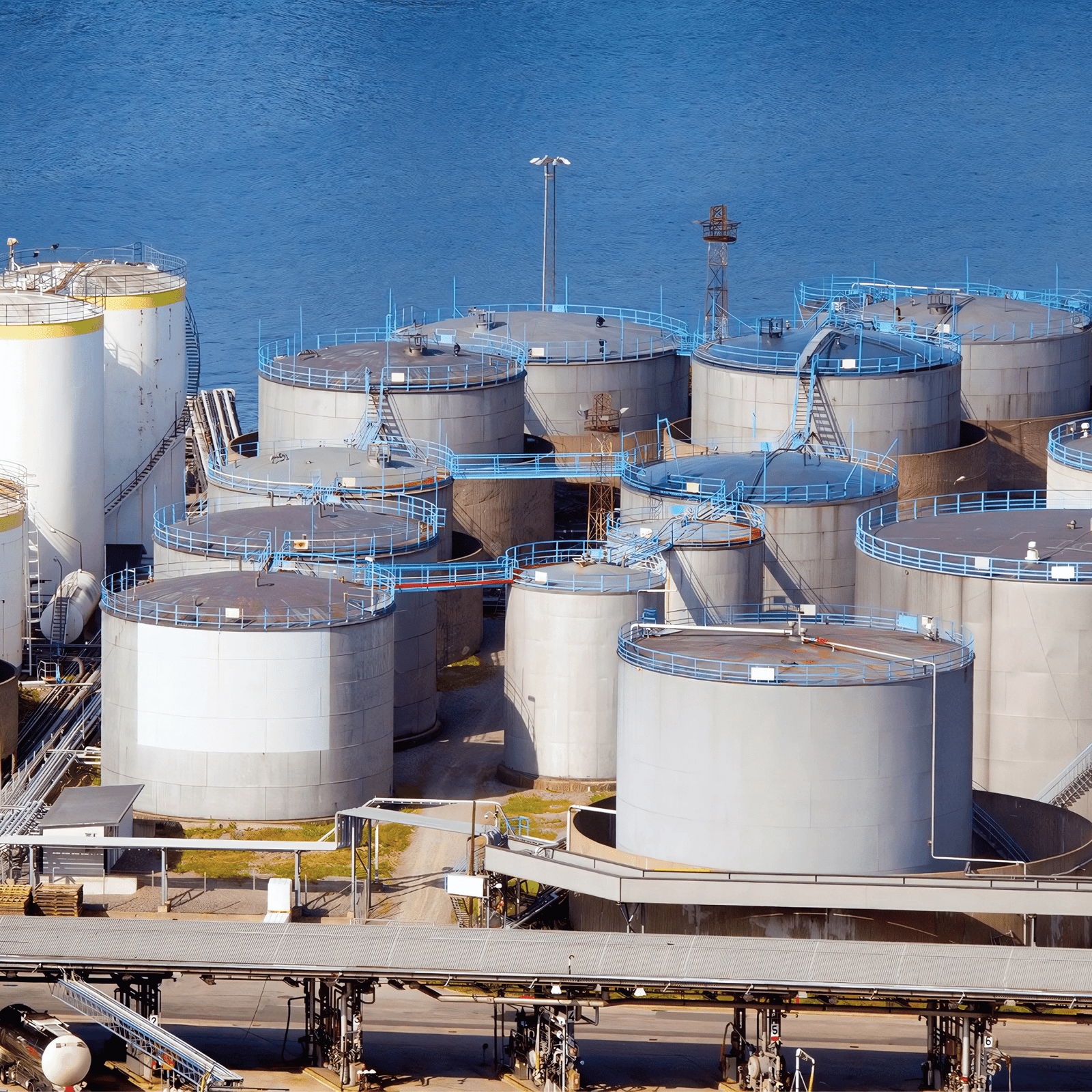

Fire Suppression Systems in the Oil & Gas Industry

Fire Suppression Systems in the Oil & Gas Industry

The oil & gas industry operates in high-risk environments where fire hazards pose a significant threat to operations, equipment, and personnel. Given the presence of highly flammable substances, implementing an advanced fire suppression system is crucial for ensuring safety and preventing catastrophic incidents.

Role of Fire Suppression Systems in Oil & Gas Facilities

Fire suppression systems are strategically installed in key operational areas such as control rooms and metering stations to mitigate fire risks. These systems detect, control, and extinguish fires rapidly, minimizing downtime and damage

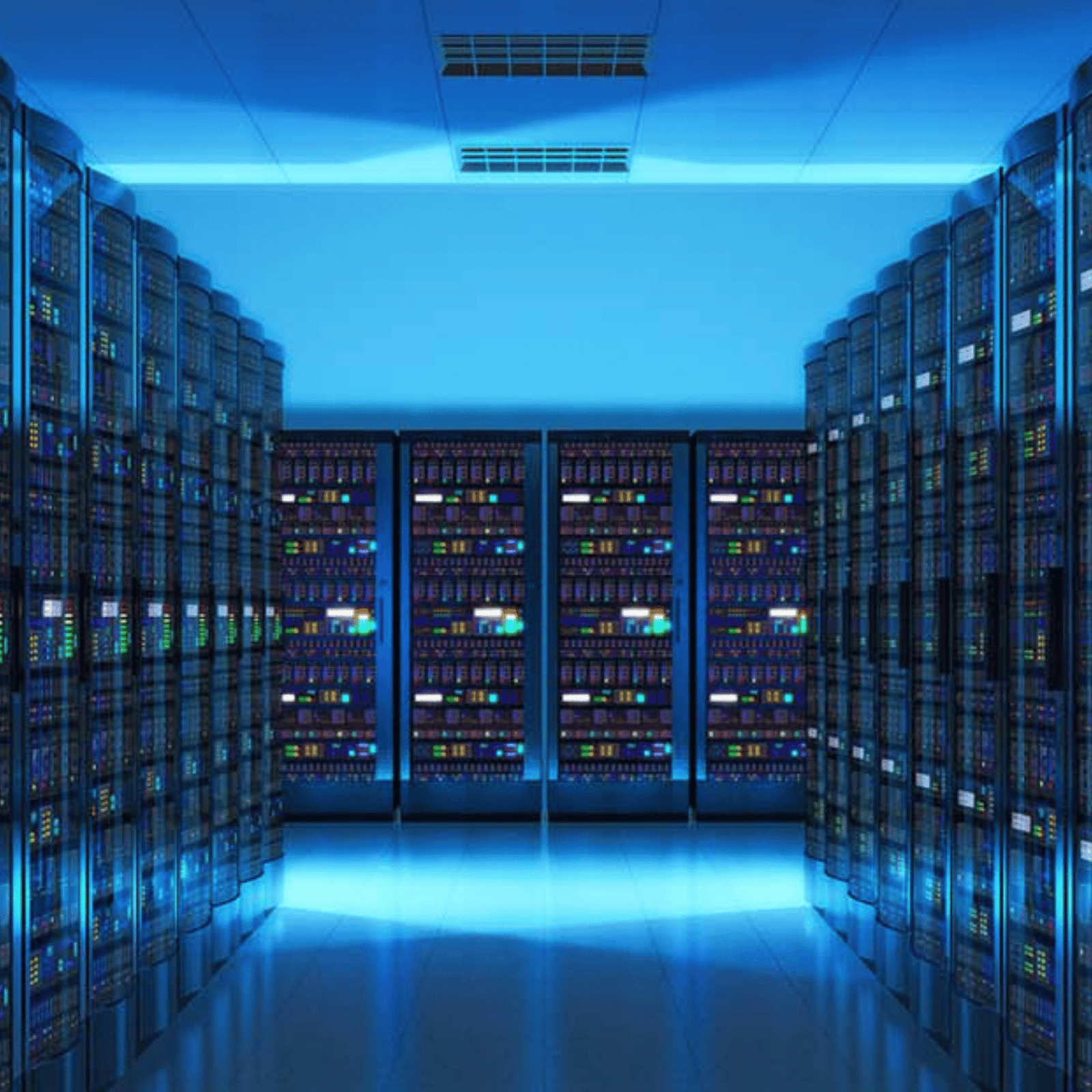

1. Fire Suppression in Control Rooms

Control rooms serve as the nerve center of an oil refinery and are equipped with sophisticated monitoring and control systems. Operators rely on electronic displays to oversee refinery processes and ensure smooth operations. A fire in the control room can lead to equipment failure, disrupting critical processes.

2. Fire Suppression in Control Rooms

Metering stations play a crucial role in measuring and regulating the flow of crude oil and natural gas in pipelines. A fire in these stations can disrupt operations and lead to massive losses.

Benefits of Fire Suppression Systems in the Oil & Gas Sector

Minimizes Downtime & Financial Losses

Uncontrolled fires can lead to significant operational shutdowns, causing oil refineries and gas plants to lose revenue due to production halts. Fire suppression systems act swiftly, ensuring minimal interruption and business continuity.

Protects Expensive Equipment & Infrastructure

The oil & gas industry relies on advanced machinery, electronic monitoring systems, and control room equipment. Fire suppression solutions, particularly clean agent fire suppression systems, help protect this valuable infrastructure by extinguishing fires without damaging sensitive electronics.

Ensures Personnel Safety

Employees working in control rooms and metering stations are at risk of exposure to fires and explosions. Advanced fire suppression systems provide quick and automatic response, reducing the likelihood of injuries and fatalities.

Prevents Environmental Hazards

Fires in crude oil and natural gas facilities can lead to oil spills, toxic emissions, and large-scale environmental damage. Effective fire suppression measures help contain fires before they escalate, reducing the risk of pollution and legal liabilities.

Ensures Compliance with Industry Safety Regulations

Regulatory bodies, such as OSHA and NFPA, mandate stringent fire protection standards for the oil & gas industry. Implementing certified fire suppression systems ensures compliance with these regulations, preventing penalties and enhancing operational credibility.

Cryptzo provides Clean Agent Fire Extinguishing Systems, offering both Chemical Fire Suppression and Inert Gas Fire Suppression Solutions across India. Designed with environmental sustainability in mind, our systems ensure efficient fire protection with key features such as multi-fire capability, rapid response, minimal residue, eco-friendliness, and seamless integration into various infrastructures.