IG-541

- Home

- Inert System

- IG-541

Enquire Now

Overview of IG - 541 Inert System

Tstructure and concept of IG-541 Clean Agent System Layout

How does Inert work?

IG-541 gas systems contain a mixture of inert gases: nitrogen, argon, and carbon dioxide stored as a gas in pressurized steel cylinders.

The combination of gases is released quickly into the designated area to subdue the fire through oxygen deprivation.

IG-541 systems are designed to starve flames of oxygen to deny further combustion, but to also allow enough for humans in the immediate area to breathe and make a safe escape.

Known for being safe to humans and the environment.

Safe for Humans and the Environment

Why 300 Bar System ?

Typical Applications

Data Processing

Area of Applications :

- Data Center

- UPS Rooms

- Electrical Rooms

- Sub-Floors Area

Communications

Area of Applications :

- Switching Equipment

- Power & Battery Area

- Cell Sites

- Standby Engine Area

Oil & Gas

Area of Applications :

- Control Room

- Metering Stations

System Components

NFPA 2001, Requirements For Minimum Values

| Agent | Class A MEC | Class A Design | Class C Design |

|---|---|---|---|

| IG-541 | 28.5 | 34.2 | 38.5 |

Environmentally Friendly

| Description | IG-541 |

|---|---|

| Ozone Depletion Potential (ODP) | 0.0 |

| Global Warming Potential (GWP) | 0.0 |

| Atmospheric Lifetime (Years) | N/A |

| SNAP (Yes / No) | YES |

| No Observable Adverse Effect Level | 43 |

| Lowest Observed Adverse. | 52 |

IG-541 Fire Suppression Agent

This IG-541 Gas Extinguishing Systems utilized a mixture of therr naturally

occurring gases

Description

Physical & Chemical Properties

| Description | Name |

|---|---|

| IUPAC Designation | N2 (52%) + Ar (40%) + CO2 (8%) |

| ASHRAE Designation | IG-541 |

| Molecular Weight. | 34 |

| Boiling Point at 760 mmHg. | 195.5°C (-320°F) |

| Freezing Point | -78.3⁰C ( -109°F ) |

| Heat Vaporization @B.P | 94.7Btu/ib |

| Ozone Depletion Potential.. | 0.0 |

| Atmospheric Lifetime, years. | N/A |

| Global Warming Potential.. | 0.0 |

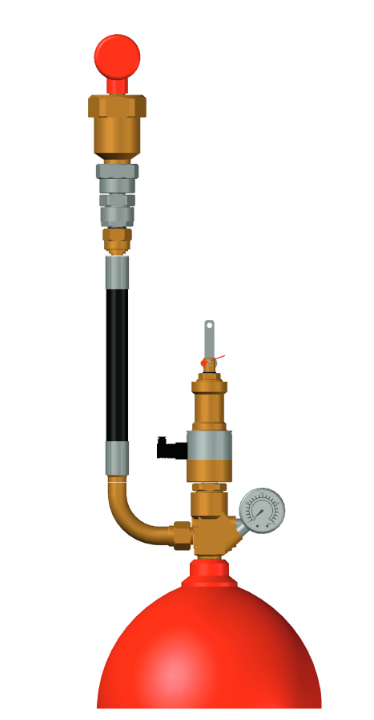

IG-541 Cylinder

Technical Specifications

IG-541 CLEAN AGENT FIRE SUPPRESSION SYSTEM

Type of System : Total Flooding System

Name of Agent : IG-541 [ N2 (52%) + Ar (40%) + CO2 (8%) ]

Design Code : NFPA-2001 Standard on Clean Agent Fire

Extinguishing Systems (Latest)

Charging Pressure : 200 Bar (2900 PSI) or 300 Bar (4350 PSI)

Discharge Time : 10 seconds maximum.

Operating Temperature : 0°C to 55°C (32°F to 130°F)

Design Concentration : Class A Fire : 34.2 % I Class C Fire :

38.5 %

Approved Agency : VdS 2454 Clean Agent Fire Extinguishing

System

A. CLEAN AGENT CYLINDER

Type : Seamless

Design Code : NFPA-2001 / IS 7285 (Part 2)

Capacity : For Seamless 80 and 140 Ltrs.

B. DISCHARGE NOZZLE

Type : 180 and 380 Degree

Material of Construction : Brass

Thread : NPT female thread

Size : 15NB, 20NB, 25NB, 32NB, 40NB & 50NB (1/2″, 3/4″. 1″,

1-1/4″, 1-1/2″ & 2″)

C. FLEXIBLE DISCHARGE HOSE

Material of Construction : Reinforced Rubber Hose.

Size : 20NB (3/4″)

D. ELECTRIC CONTROL HEAD

Operation : Electrically and Manually by Manual Plunger

Operating Voltage : 24 VDC

Operating Current : 0.5 A

Environmental Criteria : Indoor / Dry use only

Seamless Cylinder

| Nomenclature | Part Number |

|---|---|

| 80 Ltr. Seamless Cylinder With Valve & Switch-in-Gauge unit (NO), 200 Bar | 16-200080-NO2 |

| 140 Ltr. Seamless Cylinder With Valve & Switch-in-Gauge unit (NO), 200 Bar | 16-200140-NO2 |

| 80 Ltr. Seamless Cylinder With Valve & Switch-in-Gauge unit (NO), 300 Bar | 16-300080-NO2 |

| 140 Ltr. Seamless Cylinder With Valve & Switch-in-Gauge unit (NO), 300 Bar | YES |

Accessories for 2200 Bar (2900 PSI) or 300 Bar (4350 PSI) System

| Nomenclature | Part Number |

|---|---|

| 500 mm Long, Discharge hose, with 90⁰ Elbow | 20-000001-000 |

| Flexible Actuation Hose | 20-000004-000 |

| Cylinder Strap for 80 and 140 lrt. IS Cylinder | 14-000013-000 |

| Electrical Actuator | 20-000031-000 |

| Manual Actuator | 20-000033-000 |

| Pneumatic / Manual Actuator | 20-000034-000 |

| Pneumatic Actuator | 20-000036-000 |

| Solenoid Reset Tool | 20-000035-000 |

| Pilot Hose Adapter | 20-000050-000 |

| Bleed Valve | 20-000051-000 |

| Pilot Booster (T-Connector) | 20-000052-000 |

| Non Return Valve G1/8” - G1/8” | 20-000053-000 |

| DN12 Manifold Check Valve | 20-000060-000 |

| Constant Pressure Regulator G3/4" | 14-000061-000 |

| 360 Degree Nozzle | 21-000001-XXX |

| 180 Degree Nozzle | 21-000002-XXX |